.jpeg_MyXOssProcess/image/resize)

FEP-610:

Introduce: FEP is the copolymerization of tetrafluoroethylene and hexafluoropropylene, which has good thermal stability, excellent chemical inertia, good electrical insulation and low friction coefficient, making thermoplastic processing possible. The melting point of FEP crystallization is 304℃ and the density is 2.15 g/cm ³. FEP can be applied to soft plastics with lower tensile strength, wear resistance and creep resistance than many engineering plastics, but it is also chemically inert and has a low dielectric constant over a wide range of temperatures and frequencies 2.1.

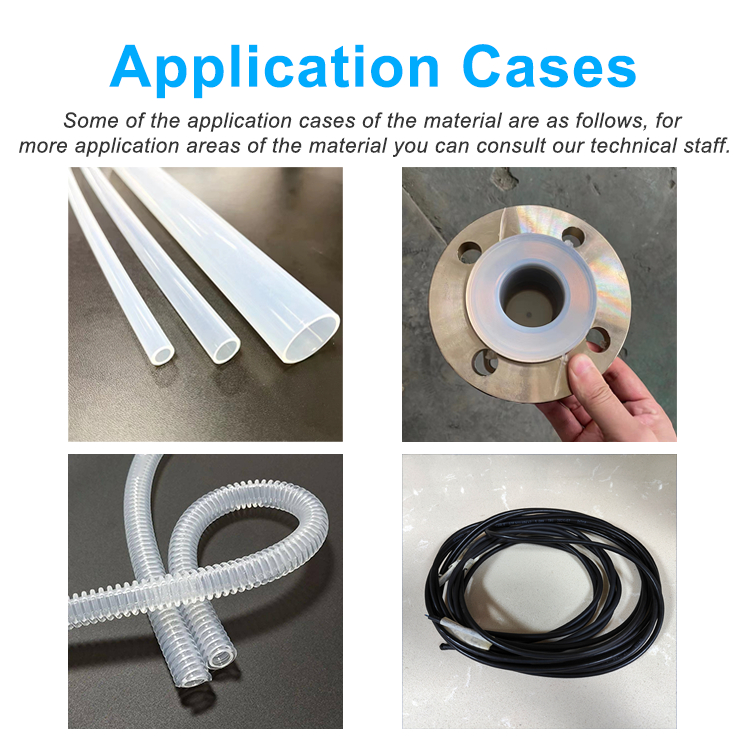

1.Its main use is for the production of pipe and chemical equipment lining, drum surface and various wires and cables, such as aircraft hook wire, booster cable, alarm cable, flat cable and oil well logging cable.

2.FEP films can be used as thin coatings for solar collectors.

.jpeg_MyXOssProcess/image/resize,w_100/quality,q_100)